Acrylic

Our acrylic can be CNC router cut but usually it is laser cut. This allows intricate shapes and letters to be cut to within 0.5mm accuracy. We operate 2 lasers with a bed size of 3050 x 1500mm and several smaller lasers with bed sizes of 1600 x 1000mm.

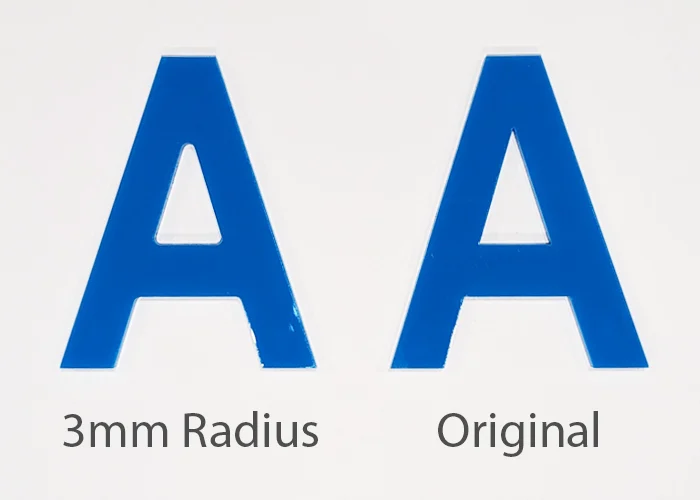

Acrylic is a relatively brittle material, whenever you have sharp internal corners there is a risk that the acrylic can crack if it is flexed too much. To combat this we would usually give any internal corners on pieces over 500mm a radius of between 1mm and 3mm depending on the size of the letter, this relieves the stress on the material and is generally not noticeable.

Acrylic is a relatively brittle material, whenever you have sharp internal corners there is a risk that the acrylic can crack if it is flexed too much. To combat this we would usually give any internal corners on pieces over 500mm a radius of between 1mm and 3mm depending on the size of the letter, this relieves the stress on the material and is generally not noticeable.

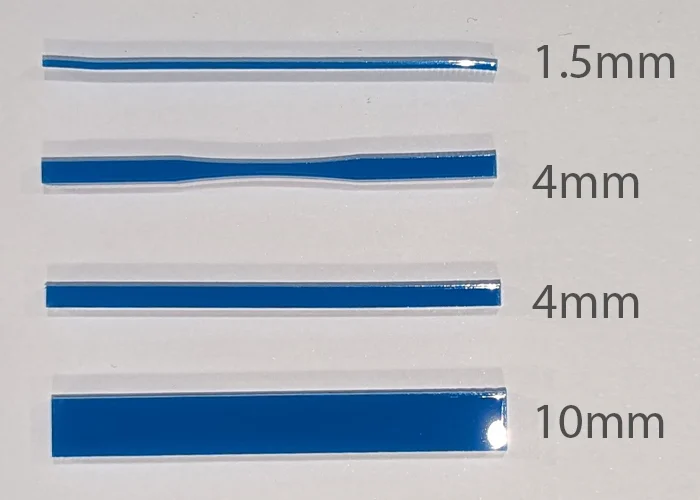

As acrylic is laser cut we can cut strokes down to 2.5mm in parts or 4mm minimum if it is a continuous stroke width. Strokes thinner than this will cut but the heat generated will warp the material.

As acrylic is laser cut we can cut strokes down to 2.5mm in parts or 4mm minimum if it is a continuous stroke width. Strokes thinner than this will cut but the heat generated will warp the material.

Aluminium Composite

Our aluminium composite is router cut and we generally use a 3.2mm diameter cutter. Our machines are all 3050 x 2030mm so this is the largest possible piece we can cut. Please be aware that although we can cut to this size we may not be able to deliver at this size to all of the country due to courier restrictions.

We would recommend a minimum stroke width of 5mm for aluminium composite, thinner than this can make the material weaker and easily deformed. Also, on smaller letters if the gaps between the strokes on letters are less than 3.2mm the cutter will not be able to pass through and may make the letters look deformed.

We would recommend a minimum stroke width of 5mm for aluminium composite, thinner than this can make the material weaker and easily deformed. Also, on smaller letters if the gaps between the strokes on letters are less than 3.2mm the cutter will not be able to pass through and may make the letters look deformed.

Foam PVC

Our foam PVC is router cut and we generally use a 4mm diameter cutter as these are less prone to snapping when cutting through thicker materials. Our machines are all 3050 x 2030mm so this is the largest possible piece we can cut. Please be aware that although we can cut to this size we may not be able to deliver at this size to all of the country due to courier restrictions.

We would recommend a minimum stroke width of 5mm for foam PVC. Also, on smaller letters if the gaps between the strokes on letters are less than 4mm the cutter will not be able to pass through and may make the letters look deformed. At sizes below 100mm high we would recommend using acrylic as you will get a better cut and finish for a very similar price.

We would recommend a minimum stroke width of 5mm for foam PVC. Also, on smaller letters if the gaps between the strokes on letters are less than 4mm the cutter will not be able to pass through and may make the letters look deformed. At sizes below 100mm high we would recommend using acrylic as you will get a better cut and finish for a very similar price.

Fixings

We can supply our flat cut letters with no fixings for you to apply your own, with VHB double sided tape or EasyClick sign locators.

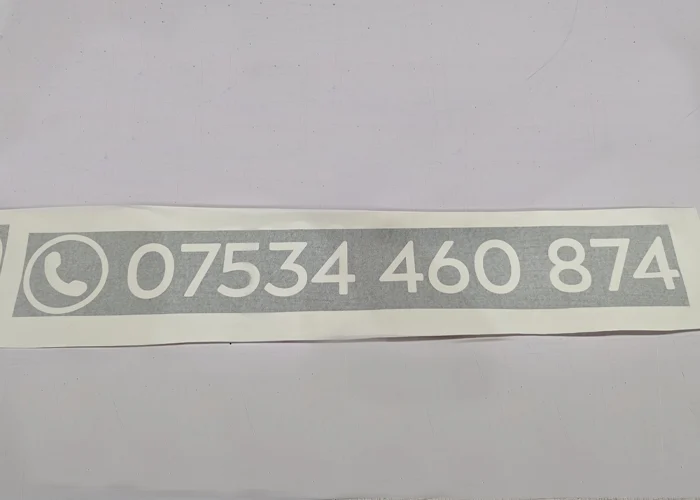

We would recommend a minimum stroke width of 4mm for double sided tape. On most materials we use 3M GPH110 tape, for some acrylics which are more translucent we use a clear VHB tape so that it shows through to the face less.

We would recommend a minimum stroke width of 4mm for double sided tape. On most materials we use 3M GPH110 tape, for some acrylics which are more translucent we use a clear VHB tape so that it shows through to the face less.

Templates

Our flat cut letters can be supplied with paper templates, vinyl templates or cardboard templates. Each has it’s own best use situations with a guide offered below.

For letters with VHB tape of a small to medium size this is ideal, once applied it does not move accidentally allowing accurate positioning of the letters.

For letters with VHB tape of a small to medium size this is ideal, once applied it does not move accidentally allowing accurate positioning of the letters.

For letters with VHB tape of a larger size this is ideal, once applied it can move slightly whilst positioning the letters but at a larger size this would not be noticeable.

For letters with VHB tape of a larger size this is ideal, once applied it can move slightly whilst positioning the letters but at a larger size this would not be noticeable.

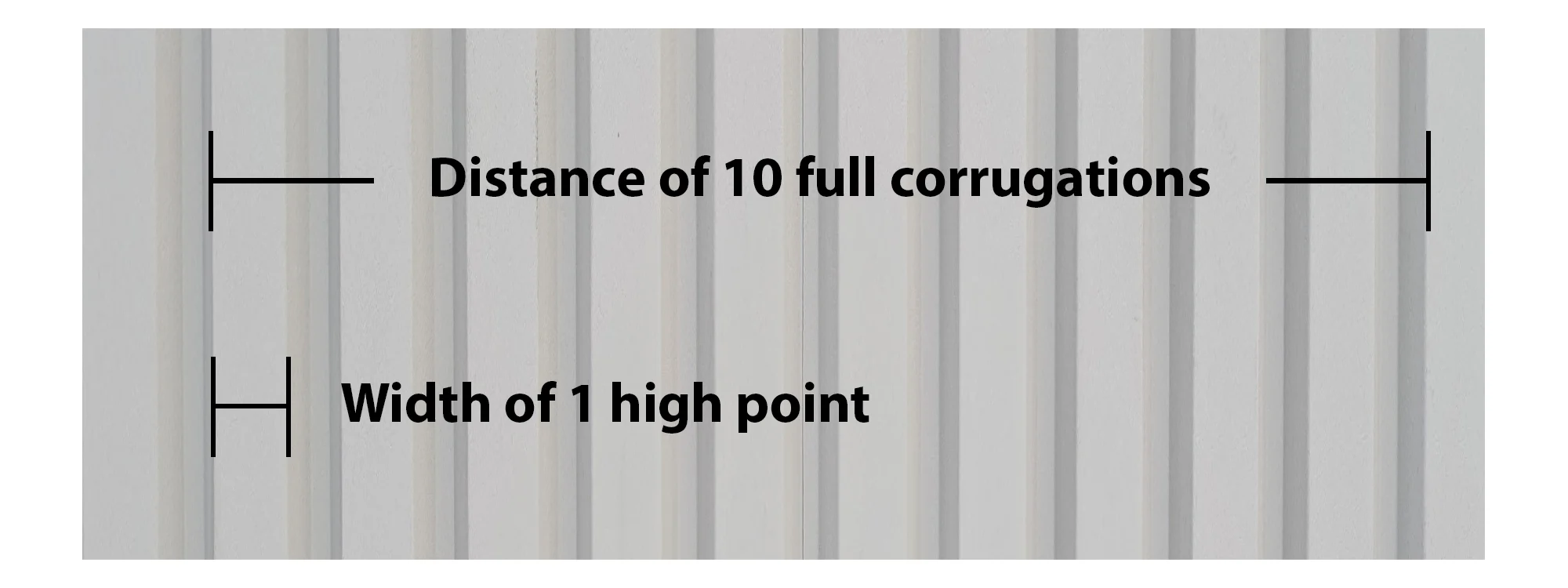

For letters with sign locators being fitted to cladding we need the measurements of where the raised parts of the cladding are to enable us to only fit locators in these parts. The easiest way to do this is to measure the overall width of 10 corrugations from left edge to left edge (or top to top). Then measure the width of one raised part from left edge to right edge. This will allow us to draw up accurate markings on the template so that all fixings are on the raised part of the cladding. On very large sets of letters you may need to occasionally split the template to readjust to the raised parts by a millimetre or two.

For letters with sign locators being fitted to cladding we need the measurements of where the raised parts of the cladding are to enable us to only fit locators in these parts. The easiest way to do this is to measure the overall width of 10 corrugations from left edge to left edge (or top to top). Then measure the width of one raised part from left edge to right edge. This will allow us to draw up accurate markings on the template so that all fixings are on the raised part of the cladding. On very large sets of letters you may need to occasionally split the template to readjust to the raised parts by a millimetre or two.

Smaller letters that are to be fitted to cladding may need to be attached to clear acrylic bars which are then in turn fixed to the cladding.